Flanges

Home / Products

About Flanges

The type of flanges is regulated based on different country norms or connection types, and the flanges are produced in different sizes according to reasons of using. This material is chosen due to its ability to withstand the highest heat and pressure levels that will apply the area to be used, the rate at which the pipe may get corroded and the area where the flange will be used.

Similarly besides flanges which the widest photo figurative facet of joining today, they are mostly used in the systems, they provide various benefits. Regarding the place of use, materials have to be completely different like brass, copper and irons or those usual metals. The second of all is that it is quite convenient as it enables you save time in pipe system maintenance. We so called create each type of flange and pipe range on demand according to your individual needs.

Pipe flanges

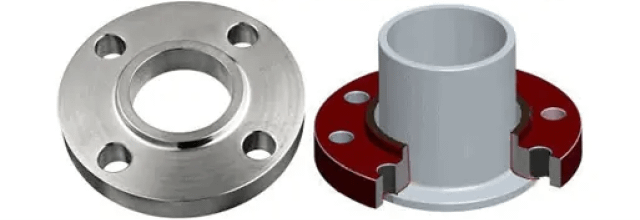

Pipe flanges manufacturer are a very important element for connecting different types of pipes, valves, pumps and other similar sewage equipment together. They are a kind of protective systems installing to join the piping with various types of equipment.

Grades in Flanges

⇒ Stainless Steel F304 Flanges

⇒ Stainless Steel 304L Flanges

⇒ Stainless Steel 304H Flanges

⇒ Stainless Steel Type 316 Flanges

⇒ Stainless Steel 316L Flanges

⇒ Stainless Steel 317 Flanges

⇒ Stainless Steel 317L Flanges

⇒ Stainless Steel 321 Gaskets

⇒ Stainless Steel 310 Flanges

⇒347 Stainless Steel Flanges

⇒ Type 904 Stainless Steel Flanges

⇒ Carbon Steel A105 Flanges

⇒ Carbon Steel A694 Flanges

⇒ Carbon Steel F42 Flanges

⇒ Carbon Steel Grade 46 Flanges

⇒ 52 Carbon Steel Flanges

⇒ Carbon Steel 56 flanges

⇒ Carbon steel 60 Flanges

⇒ Carbon Steel 65 Flanges

⇒ Carbon Steel 70 Flanges

⇒ ASTM A516 Grade 60/70 Flanges

⇒ F1 Alloy Steel Flanges

⇒ Alloy Steel FS Flanges

⇒ F9 Flanges

Alloy Steel F11 Flanges

⇒ Alloy steel F22 flanges

⇒ F91 Alloy Steel Flanges

⇒ Monel 400 Flanges

⇒ Monel K500 Flanges

⇒ Inconel Alloy 600 Flanges

⇒ Inconel Alloy 601 Flanges

⇒ Inconel Alloy 625 Flanges

⇒ Inconel Alloy 718 Flanges

⇒ Inconel alloy 725 flanges.

⇒ Hastelloy C22 Flanges

⇒ Hastelloy C276 Flanges

⇒ Hastelloy 82 Flanges

⇒ The nickel alloy UNS 2201 flanges

⇒ Nickel Alloy UNS 2200: 2

Enabling the two substances to be coupled by means of inner and outer sides clamp parts is fluency connection. Along the slopes, then, put decking which will be useful for eliminating troubles that might occur. The next will be, for ensuring the firmly holding of these bolts among the flanges. Sealing elements are used for the purposes of prevention of leak but this is done after the process of tightening those flanges. In order to have a healthy seal, care should be paid to flanges to be matched and bolts to be tightened with the recommended torque.

Stainless Steel Flanges and Fittings Pros.

The stainless steel flanges is second to none on the resistance to corrosion as a result of chromium addition, which creates an oxide film at the surface. This protective layer serves as a barrier against the harmful elements however; corrosion and rust would still take place if the protective layer is degraded. Stainless steel is long lasting, robust and easy to care for, and it is self-healing. The chromium barrier found on material surface can be re-formed to heal the limited damage to the surface.

Correct flange and fitting maintenance is key advice to prevent rust and wear surface of the equipment. There is a possibility for corrosion to take place if the suit is in contact with salt, including the seaside air and road salt. For high-quality stainless steel components, make sure that the appropriate grade of stainless steel for your application is chosen and corrosive substances and rust are subsequently removed using suitable solvents as part of regular maintenance.

Flexibility is also one of the advantages of this choice. All stainless steel components can be expatiated upon or fabricated to your specific specs for custom made fittings or flanges.

What Applications for Stainless Steel Flanges ?

Residential, commercial and industrial piping systems utilize stainless steel flanges and fittings as well. Strength, resistance to corrosion, temperature, pressure, and flow, are the four qualities that make stainless steel one of the most widespread materials used for gas or liquid transport, as well as in any chemical processing, marine and sanitary applications where corrosion resistance is necessary. Please appeal to the related standards or call us if you can’t select the right stainless steel grade or type of flange for your purpose.

The Most Frequently Used Stainless Steel Flanges.

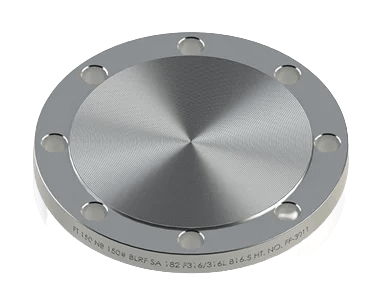

Most frequently, the flanges are threaded or welded, and the gasket, which helps to connect the flanges’ ends, is used for pipeline access. These flanges comprise of socket weld flanges, blind flanges, weld-deked flanges and slip¬ on flanges and they just provide an example of the varieties available. Letting the connection serve to disassemble the pipes or remove the components will be an easy process.

Stainless steel flanges available in various standards such as AWWA, DIN, metric, and ANSI Class-rated are offered. In accordance with these standards, you may be able to identify one of the most common flange types as well as obtain custom machining for your specific needs and application.

Weld-Neck

Slip-On or Ring

Socket Weld

Lap Joint

Blind Raised Face Flanges

Groove flanges

Threaded flanges

Plate flange

These also include threaded couplings, nipples, braided pump connectors, 90-degree elbows and other components in stainless steel. When selecting the components of stainless steel piping system for a intended application, obey the standard of the same application.

What Flanges and Fitting Standards Apply to Stainless Steel Parts?

Multiple standards determine what the chemical composition, dimensionality; pressure ratings should be as well as other required limits of fittings and flange materials for piping systems. AWS AWWA C228 Streets the minimum material requirements and dimensions of stainless steel flanges that are used in stainless steel piping systems in the systems.

Selecting of Stainless Steel Grade intended for flanges you need to purchase matching stainless steel flanges, fittings, and accessories of the required grade for the application you intend. The most common alternatives in industry are 304 and 316 stainless steel, which are chosen especially for their high strength even when subjected to heavy stress. The right grade of stainless steel as well must be chosen to managing possible corrosion. Employing a substituted grade at sealed conditions out at high temperature might have an erratic reaction or damage the piping system. Selecting the right size of piping system according to the relevant case will save you the damage of malfunction or early failure.

ASTM A182 emphasizes those forged or rolled piping system components which are utilized for the purposes of high-temperature service.

ASME B16.5 forms the dimensional standard for pipe flanges and other fittings, taking into consideration the stainless steel version of the product.

ASME B16.34 designates pressure/temperature rating of the valves that are connected to flanges by threading and welding. B16.47 deals with oversized steel and stainless steel flanges alone.

Why platinex for flanges

Quality Assurance

Quality is our main goal. We maintain stringent quality control procedures to make certain that our flanges meet the highest performance and reliability criteria. We follow rigorous tests and inspection procedures to ensure our products meet all industry standards and customers specifications.

Custom Solutions

Furthermore, we attend to tailor-made flange requirements that accommodate and satisfy your general design needs and preferences. Our engaged engineering and technology crew will work hand in hand with you by way of designing and manufacturing made to order flanges best suited to your specific application needs.

Export Services

We have our worldwide network and the logistics know-how which assume the existence of exporting services to the global clients. Our export team is prepared to assist you in every aspect that you require such as shipping, documentation, and customs clearance. They will ensure that all your orders are properly accompanied and received within the agreed time frame and in perfect condition.